The GJ Series from SOUND MACHINERY is engineered for the precise molding of PE pipe fittings.

Featuring an independent V-type injection and plasticizing structure, this machine delivers enhanced efficiency, stability, and energy savings.

Fully compliant with the latest national and industry safety standards.

Conforms fully to the latest national and industry safety standards, ensuring operational safety and long-term reliability.

Incorporates a special metal-sealed structure that effectively supports high-pressure injection without leakage, while maintaining excellent plunger venting performance.

Uses a double-step injection structure with independent pre-injection, allowing for faster material preparation and efficient molding cycles.

The compact and purpose-built V-shaped injection configuration separates the plasticizing and injection actions, optimizing machine rhythm and improving production throughput for PE pipe fittings.

The V-type injection structure and independent plasticizing mechanism ensure better control over material flow and melt consistency, minimizing fluctuations during the injection process.

Engineered for stable high-pressure performance, the system maintains tight sealing and consistent pressure output, resulting in high dimensional accuracy in molded parts.

Features a highly optimized servo energy-saving system, capable of adjusting power consumption based on real-time load demands.

Meets or exceeds national-level energy consumption standards, significantly reducing electricity costs while enhancing overall system efficiency.

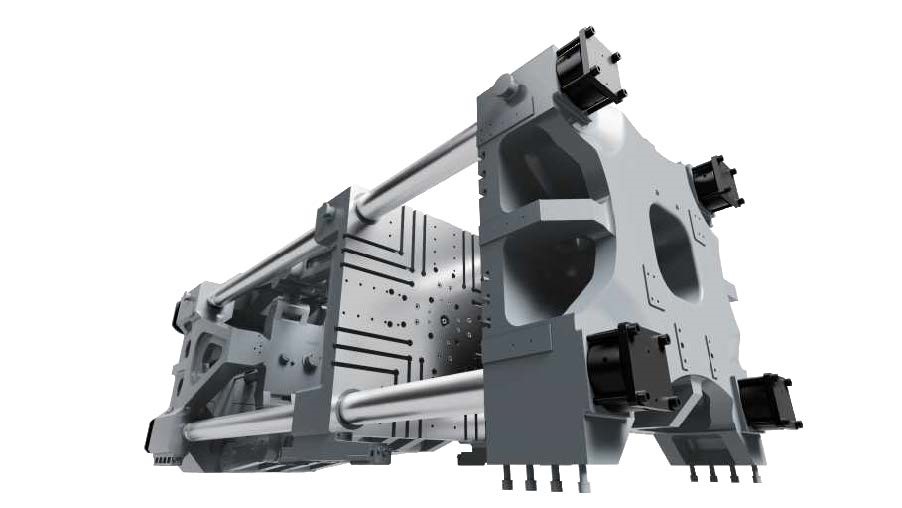

Clamping Unit

●A negative back angle design is applied to the clamping system, enabling smoother and faster mold opening and closing operations.

●The machine features a three-platen box structure, optimized through UG finite element analysis to ensure high strength, excellent rigidity, and minimal deformation under load.

●The moving platen adopts a static pressure support system, providing increased load-bearing capacity and operational stability.

●A hollow box-type base allows for more convenient installation of core cylinders at the bottom, enhancing mold adaptability.

●The widened sliding door design supports easy integration of long-stroke core-pulling molds and improves operator access.

●Template components are equipped with sliding take-up carts, allowing for ergonomic and user-friendly mold handling.

●The servo-driven safety sliding door features anti-pinch protection and ensures smooth, fast, and reliable operation.

●A side-positioned safety switch enhances operational safety and simplifies access control.

●A rotary computer-controlled remote door system is included for convenient and intelligent remote operation.

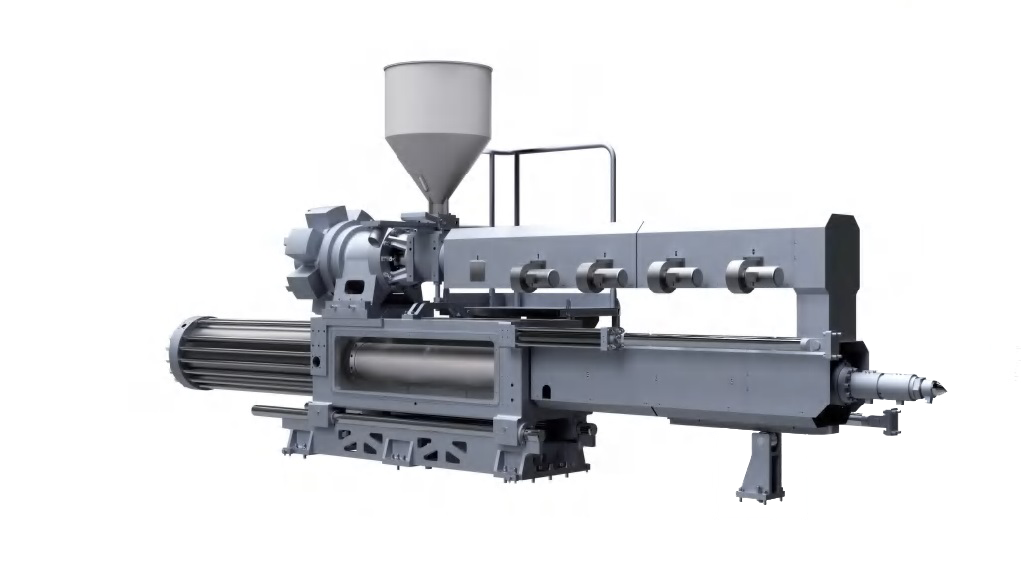

Injection Molding Unit

●Utilizes a double-stage extrusion compound structure, supporting an injection volume range from 5,000 cm³ to 5,000,000 cm³, suitable for both medium and large-scale production requirements.

●Compared with conventional injection units of the same output capacity, this system saves up to 35% in space, improving layout flexibility and factory utilization.

●Equipped with a specialized mixing screw design, achieving ultra-low energy consumption of less than 0.35 kW/kg, significantly reducing operational costs.

●The V-shaped injection structure effectively eliminates residual resin and prevents carbonization, ensuring superior melt quality and reducing material waste.

●Features an original mechanical spool valve system, which maintains structural integrity under stress, resists deformation and wear, and provides enhanced safety and long service life.

●Incorporates a metal-ring sealed plunger mechanism, offering superior sealing performance compared to traditional ring designs, thereby improving injection stability and reducing leakage risks.

SSR Barrel Temperature Control System

●With non-contact control technology, raw materials are seamlessly integrated into a closed-loop temperature control system immediately upon entering the feeding port.

●This significantly enhances the accuracy and efficiency of the injection unit by preventing issues such as material agglomeration and underfeeding, which commonly lead to reduced injection precision.

●The system also features a roller-type sliding structure, enabling quick and convenient raw material replacement for operators, thereby improving operational efficiency and user experience.

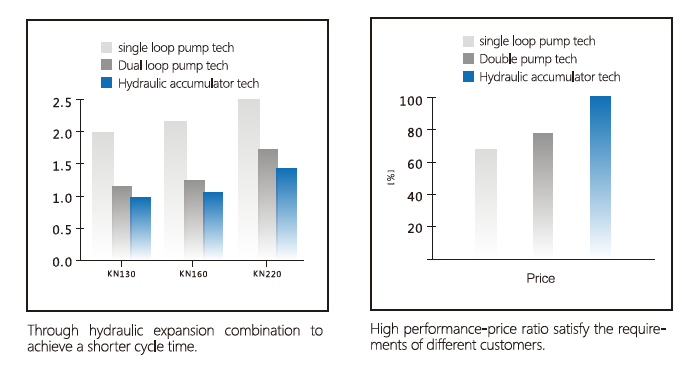

High-efficient and stable hydraulic mold unit

●The whole machine adopts high-performance hose + DIN standard hydraulic joint, no welding, no oil leakage and no pollution;

●Multi-pump combination technology, servo electric injection technology, and hydraulic accumulator technology realize the independent movement of each movement axis, making high efficient production so simple;

●Through the hydraulic expansion combination, a shorter cycle period is realized; strong selectivity and high cost performance to meet the requirements of different customers;

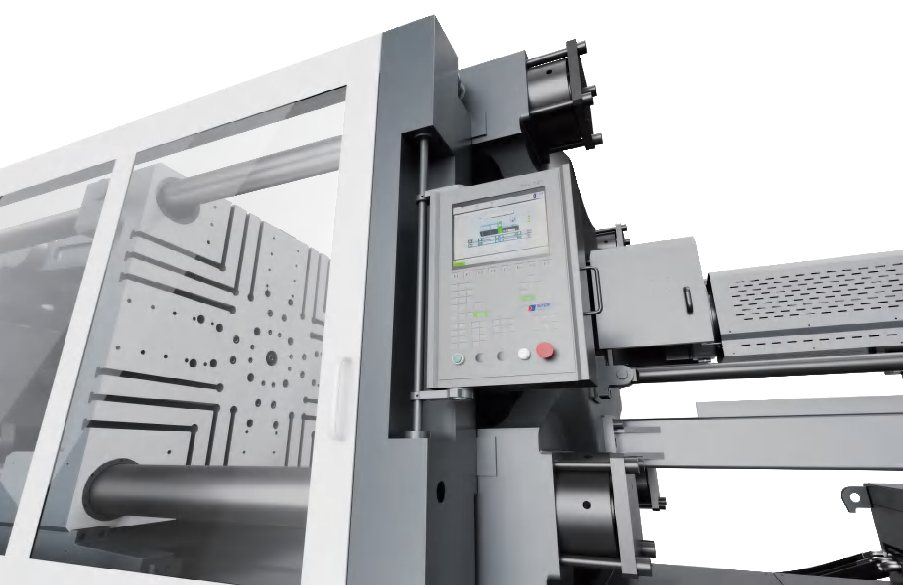

Precise Intelligent Control System

The whole series have equipped with a large-screen controller as standard, and a friendly UI interface to better convey information;

Equipped with SPC quality control management system as standard to help realize the continuous stability and predictability of the manufacturing process, improve production capacity, product quality and reduce costs;

SVP servo pump, precise control, fast response, convenient system maintenance and energy saving The powerful software control function makes the complex injection molding process simple and easy to operate;

The main electrical components are all from the imported brands such as Schneider, ABB, Fuji, Eaton, etc., which greatly improves the service life and stability;

Human-computer interaction

Open industrial 4.0 expansion interface, (U77, OPC, etc., MES requires additional fees) to open a new era of smart factories

Automated, intelligent, and modern computers are conducive to central data collection, analysis, and backup, and at the same time realize data interaction and full-line automation with auxiliary equipment such as robot, mold temperature controllers, and chiller, forming an exclusive customer Internet of Things management solution for Injection Molding Machines Program;

Friendly and simple operating software, so that users can grasp the production status of the machine at any time and anywhere, respond quickly and timely, and ensure efficient production process and

high-quality output.

Contact: Mr.Cheng

Phone: 86 15867460640

E-mail: Info@soundimm.com

Whatsapp:8615867460640

Add: 618 Huancheng North Road, Deqing County, Huzhou City, Zhejiang Province, CHINA

We chat